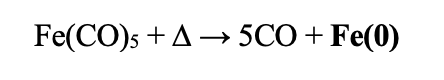

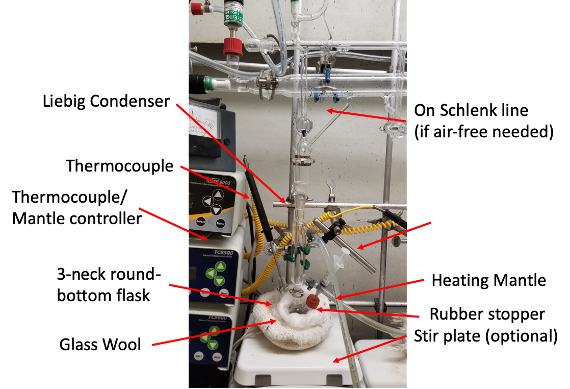

This reaction requires an air-free setup. Follow the procedure for chromium above or use a Schlenk line as shown.

Place the 2D material in the round-bottom flask, evacuate and flushed with N2 gas. In a glovebox, create two stock solutions. Stock solution 1 should be 5 mL of anhydrous acetone. Stock solution 2 should be created from 0.01 g of iron pentacarbonyl dissolved in 3 mL of air free acetone. Inject the first stock solution of anhydrous acetone into the round-bottom flask and heat to just below reflux (~45-48°C). Dropwise, inject in the iron (solution 2) over the course of 1.5 hours. After all solution has been injected, allow the mixture to sit just below reflux for 1 more hour. Remove substrates or material from the solution and rinsed with hot acetone and hot ethanol, exposing to air at this point is okay.

Ideally, and if the reaction is done to perfection, the solution should remain transparent. Sometimes under excess light, it is possible to crash out all the iron – which will appear as a dark black or red precipitate once exposed to air. This is rare to get. Rinse the substrate or material with ethanol and acetone (25°C).

| Fe(CO)5 | acetone | time | ~ intercalated in Bi2Se3 |

|---|---|---|---|

| 0.01 g | Total = 8 mLs | 2.5 hours | 8 atm % ± 3% |

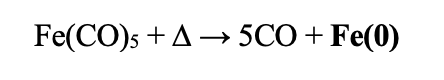

M. Wang, D. Williams, G. Lahti, S. Teshima, D. Dominguez-Aguilar, K. J. Koski, Chemical intercalation of heavy metal, semimetal, and semiconductor atoms into 2D layered chalcogenides. 2D Materials, 5, 045005 (2018)