Note:

The procedure below is the published procedure. However, it is possible to intercalate W using acetone rather than octadecene and heating to only 52C following a similar procedure as iron intercalation.

• Freeze-Pump-Thaw: On a Schlenck line, place octadecene in a heavy-walled (critical) single-neck round bottom flask or a sealed Schlenk flask. Freeze it by immersing in liquid nitrogen. Once frozen, open the flask to high vaccum and pump for about 5 minutes. Keep the octadecene in liquid N2. Place solvent back under N2 and let thaw. Repeat 3 times. Remove solution using a needle and syringe into a N2 filled septa vial.

• Purging: So, this is what I do for octadecene. This is really hard on a vacuum pump so use a robust pump (Varian DS Rotary Vane Pump). Place octadecene in a round bottom flask. Heat to 110°C and place under vacuum for about 30 minutes. Refill with N2. Keeping under N2 atmosphere, bubble N2 or Ar into the flask using a long needle. Bubble for about an hour or two.

Store degassed octadecene in a glovebox.

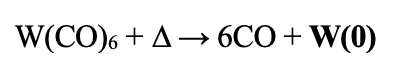

Setup the reaction as above. Place the 2D material in the round-bottom flask, evacuate and flush with N2 gas. In a glovebox, create two stock solutions. Stock solution 1 should be 5 mL of degassed octadecene. Stock solution 2 should be 10 mM of tungsten hexacarbonyl in 20 mL of degassed octadecene. This is approximately from 0.07 g of tungsten carbonyl dissolved in 20 mL of degassed octadecene. Inject the first stock solution of octadecene into the round-bottom flask and heat to 150-170°C. Dropwise, inject in the tungsten (solution 2) over the course of 2-3 hours. After all solution has been injected, allow the mixture to sit just below reflux for 1 more hour. Remove the substrate and rinse repeatedly with acetone to remove excess octadecene.

| W(CO)6 | Octadecene | Time | ~ Intercalated in Bi2Se3 |

|---|---|---|---|

| 0.01 g | 25 mL | 3 hours | 4 atm % ± 2% |

M. Wang, D. Williams, G. Lahti, S. Teshima, D. Dominguez-Aguilar, K. J. Koski, Chemical intercalation of heavy metal, semimetal, and semiconductor atoms into 2D layered chalcogenides. 2D Materials, 5, 045005 (2018)